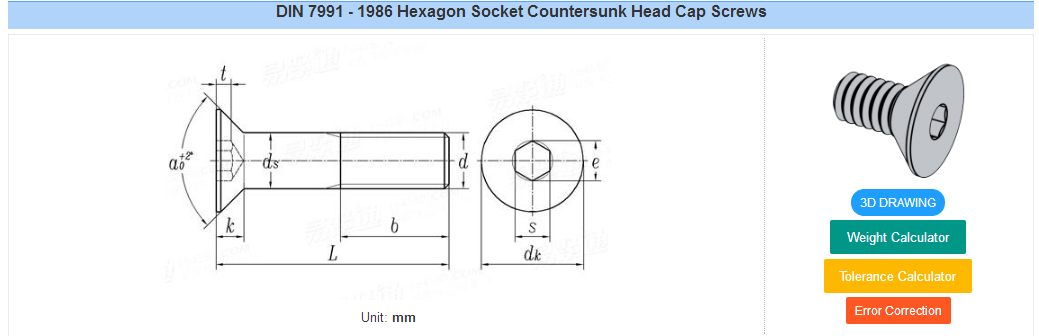

Stainless Steel Hexagon Socket Countersunk Head Cap Bolt DIN 7991

Inkcazelo emfutshane:

Min.Order Ubuninzi:1000PCS

UKUPAKAJWA:IBHEKI/IBHOKISI ENEPALLET

I-PORT:TIANJIN/QINGDAO/SHANGHAI/NINGBO

UKUNIKELWA: I-5-30DAYS NGE-QTY

INTLAWULO:T/T/LC

Ukubonelela ngeAmandla: 500 TON NGENYANGA

Iinkcukacha zeMveliso

Iithegi zeMveliso

Ingcaciso yeMveliso:

| Igama lemveliso | IHexagon Socket Countersunk Head Cap Bolt |

| Ubungakanani | M3-24 |

| Ubude | 6-100mm okanye njengoko kufuneka |

| IBanga | SS304/SS316 |

| Izinto eziphathekayo | Yenziwe ngentsimbi eshayinayo |

| Unyango lomphezulu | Ngokucacileyo |

| Umgangatho | DIN/ISO |

| Isatifikethi | ISO 9001 |

| Isampulu | Iisampuli zasimahla |

Ukusetyenziswa:

Phezulu komngxuma wokuxhoma kwisiqwenga sokudibanisa, i-socket ye-conical ejikelezayo engama-90 icutshungulwa, kwaye intloko ye-flat machine screw ikule sokethi ejikelezileyo, ehlanjululwayo kunye nomphezulu wesiqwenga sokudibanisa. Izikrufu zomatshini weflethi zikwasetyenziswa kwezinye izihlandlo ezinentloko engqukuva izikrufu zomatshini weflethi. Olu hlobo lwe-screw luhle kakhulu kwaye lusetyenziswa kwiindawo apho umphezulu unokuvumela ukukhupha okuncinci.

Kusetyenziswa kwanjani?

Uninzi lwezikrini ze-countersunk zisetyenziselwa kwiindawo apho umphezulu wenxalenye awukwazi ukuphakanyiswa emva kokufakwa. Zimbini iindidi zamalungu ekufuneka zibotshelelwe. Ubukhulu bentloko, emva kokuba i-screw iqinisiwe, inxalenye yentambo ye-screw ayisayi kungena kumngxuma odibeneyo. Kule meko, i-countersunk head screw ngokuqinisekileyo inokuqiniswa.

Ikhowuni yentloko yesikrufu sentloko ye countersunk ineengile yecone eyi 90 °. Ngokuqhelekileyo, i-engile ephezulu ye-drill bit esanda kuthengwa yi-118 ° -120 °. Abanye abasebenzi abangaqeqeshwanga abawazi lo mahluko engile, kwaye kaninzi sebenzisa 120 ° drill Reaming, nto leyo ebangela ukuba izikrufu zentloko countersunk azikrwitshwa xa uqinisa izikrufu zentloko countersunk, kodwa umgca ezantsi kwentloko jijwa, nto leyo. esinye sezizathu zokuba into ebizwa ngokuba yi-countersunk screws ayikwazi ukubamba ngokuqinileyo.

Izilumkiso ngexesha lokusetyenziswa:

1.I-taper yomngxuma wokubuyisela kufuneka ibe ngama-90 °. Ukuyiqinisekisa, kungcono ukuba ngaphantsi kwe-90 °, ingabi ngaphezu kwe-90 °. Eli liqhinga eliphambili.

2. Ukuba ubukhulu bephepha lesinyithi bungaphantsi kobunzima bentloko yesikrufu sentloko ye-countersunk, unokutshintsha isikrufu esincinci, okanye kunoko wandise umngxuma omncinci kunokwandisa umngxuma ukuze ububanzi bomngxuma osezantsi ube mkhulu. kwaye inxalenye ayiqinile.

3.Ukuba kukho imingxunya ye-screw ye-countersunk kwinxalenye, yichaneke ngakumbi ngexesha lomatshini. Emva kokuba i-drill igoso, kunzima ukubona indibano, kodwa inokuqiniswa nje ukuba impazamo incinci, kuba xa i-screw ingaqini kakhulu Enkulu (malunga no-8mm), xa kukho impazamo kuyo. umgama womngxuma, intloko yesijivu iya konakala ngenxa yokunyanzeliswa xa iqinisiwe, okanye iya kuqiniswa.

Imibuzo eqhelekileyo malunga nentsimbi engatyiwayo:

Umbuzo: Kutheni insimbi engenasici imagnetic?

A: 304 steel stainless yekaaustenitic steel stainless. I-Austenite iguqulwe ngokuyinxenye okanye kancinane ibe yimartensite ngexesha lokusebenza okubandayo. I-Martensite yimagnetic, ngoko ke intsimbi engenazibuthe ayinamagnetic okanye ayinamagnethi.

Umbuzo: Ungazichonga njani iimveliso zensimbi ezingenasici?

A: 1. Inkxaso yovavanyo olukhethekileyo lwe-potion yensimbi engenasici, ukuba ayitshintshi umbala, yintsimbi yokwenene engenasici.

2. Ukuxhasa uhlalutyo lwemichiza kunye nohlalutyo lwe-spectral.

3. Ukuxhasa uvavanyo lomsi ukulinganisa indawo yokusetyenziswa kwangempela.

Q: Zeziphi iintsimbi ezisetyenziswa ngokuqhelekileyo?

A: 1.SS201, ilungele ukusetyenziswa kwindawo eyomileyo, kulula ukurusa emanzini.

I-2.SS304, indawo yangaphandle okanye efumileyo, ukuchasana okunamandla kwi-corrosion kunye ne-asidi.

I-3.SS316, i-molybdenum yongeziweyo, ukuxhathisa ukugqwala, ngakumbi ifanelekileyo kumanzi olwandle kunye nemidiya yemichiza.

Izinto ezintlanu eziluncedo zentsimbi engatyiwayo:

1. Ubunzima obuphezulu, akukho deformation ----- Ubunzima bensimbi engenasici bungaphezu kwamaxesha ama-2 aphezulu kunobhedu, ngaphezu kwamaxesha angama-10 aphezulu kune-aluminium, ukucubungula kunzima, kwaye inkqubo yokuvelisa inzima.

I-2.I-Durable kunye ne-rusty ---- eyenziwe ngensimbi engenasici, inhlanganisela ye-chrome kunye ne-nickel idala uluhlu lwe-anti-oxidation ebusweni bezinto eziphathekayo, ezidlala indima yokugqwala.

3.Inobuhlobo kwindalo, ayinayo ityhefu kwaye ayingcolisi ------- Izinto zentsimbi engatyiwayo ziye zaqatshelwa njengezicocekile, zikhuselekile, azinatyhefu kwaye zixhathisa kwiiasidi kunye nealkali. Ayikhutshelwa elwandle kwaye ayingcolisi amanzi etephu.

4. Ubuhle, umgangatho ophezulu, osebenzayo -------- Iimveliso zensimbi ezingenasici zithandwa kwihlabathi lonke. Umphezulu wesilivere nomhlophe. Emva kweminyaka elishumi yokusetyenziswa, ayinakuze ivuthe. Ngethuba nje usula ngamanzi acocekileyo, uya kucoceka kwaye ahle, akhanye njengentsha.

Iinzuzo zemveliso:

- Precision Machining

☆ Ukulinganisa kunye nenkqubo usebenzisa izixhobo zomatshini ezichanekileyo kunye nezixhobo zokulinganisa phantsi kweemeko ezilawulwa ngokungqongqo.

- Umgangatho ophezulu wekhabhoni yentsimbi (35 #/45 #)

☆ Ngobomi obude, isizukulwana sobushushu obuphantsi, ubunzima obuphezulu, ukuqina okuphezulu, ingxolo ephantsi, ukuxhathisa okuphezulu kunye nezinye iimpawu.

- Isebenza kakuhle emalini

☆ Ukusetyenziswa kwensimbi ephezulu ye-carbon steel, emva kokulungiswa ngokuchanekileyo kunye nokwenza, kuphucula kakhulu amava omsebenzisi.

Unyango lomphezulu:

- MNYAMA

☆ Umnyama yindlela eqhelekileyo yonyango lobushushu besinyithi. Umgaqo-siseko kukwenza ifilimu ye-oxide kwindawo yesinyithi ukuhlukanisa umoya kunye nokufezekisa ukuthintela ukugqwala. I-Blackening yindlela eqhelekileyo yonyango lobushushu besinyithi. Umgaqo-siseko kukwenza ifilimu ye-oxide kwindawo yesinyithi ukuhlukanisa umoya kunye nokufezekisa ukuthintela ukugqwala.

- I-ZINC

☆ I-Electro-galvanizing yitekhnoloji yonyango yentsimbi yesiko enikezela ukuxhathisa okusisiseko kwimigangatho yentsimbi. Iinzuzo eziphambili ziyi-solderability efanelekileyo kunye nokuchasana koqhagamshelwano olufanelekileyo. Ngenxa yeepropathi zayo ezilungileyo zokuthambisa, i-cadmium plating iqhele ukusetyenziswa kwinqwelomoya, kwi-aerospace, elwandle, nakwimveliso yerediyo neye-elektroniki. I-plating layer ikhusela i-substrate yentsimbi ekukhuselweni komatshini kunye neekhemikhali, ngoko ke ukuxhathisa ukubola kwayo kungcono kakhulu kune-zinc plating.

- HDG

☆ Iinzuzo eziphambili kukuthengiswa okulungileyo kunye nokuchasana koqhagamshelwano olufanelekileyo. Ngenxa yeepropathi zayo ezilungileyo zokuthambisa, i-cadmium plating iqhele ukusetyenziswa kwinqwelomoya, kwi-aerospace, elwandle, nakwimveliso yerediyo neye-elektroniki. I-plating layer ikhusela i-substrate yentsimbi ekukhuselweni komatshini kunye neekhemikhali, ngoko ke ukuxhathisa ukubola kwayo kungcono kakhulu kune-zinc plating. I-Hot-dip zinc inokumelana ne-corrosion elungileyo, ukukhuselwa kwedini kwi-substrates yentsimbi, ukumelana nemozulu ephezulu, kunye nokumelana nokhukuliseko lwamanzi etyuwa. Ifanelekile kwizityalo zekhemikhali, iindawo zokucoca kunye namaqonga okusebenza onxweme kunye nonxweme.

IPACEJI YETHU:

1. Iingxowa ezingama-25 kg okanye iingxowa ezingama-50kg.

2. iingxowa ezinephalethi.

3. Iikhathoni ezingama-25 kg okanye iibhokisi ezinephalethi.

4. Ukupakisha njengesicelo sabathengi